- Regular maintenance of electrical systems prevents malfunctions, ensuring safety and reducing costly downtime in industrial plants.

- Servicing HVAC units is crucial for optimal performance, energy efficiency, and maintaining a safe working environment.

- A well-maintained plumbing system prevents leaks and water damage, with upgrades ensuring long-term reliability and safety.

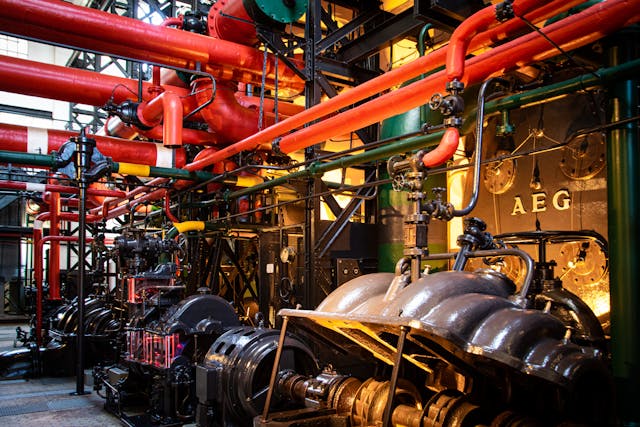

- Ensuring structural integrity and machinery maintenance is critical to the plant’s productivity and operational success.

Running an industrial plant comes with its own set of challenges, and one of the most critical aspects is maintaining the essential infrastructure. From electrical systems to HVAC units, ensuring that everything is in proper working order is crucial for the safety and efficiency of your operation. This blog will discuss key infrastructure components that you should focus on maintaining to keep your industrial plant running smoothly.

Electrical Systems

One of the most critical components of any industrial plant is its electrical system. Regular maintenance and inspections are essential to prevent malfunctions that could lead to costly downtime or even safety hazards.

Make sure to check for frayed wires, overheating equipment, and any signs of wear and tear. Consider investing in a backup power source or surge protection to safeguard against unexpected outages. Additionally, implementing an energy management system can help monitor and optimize your plant’s electricity usage.

HVAC Units

Proper ventilation and temperature control are vital for maintaining a comfortable and safe working environment in your industrial plant. Regularly servicing your HVAC units can help prevent breakdowns and ensure optimal performance. Change air filters regularly, inspect ductwork for leaks, and clean evaporator coils to improve energy efficiency and indoor air quality.

Plumbing Systems

A well-maintained plumbing system is essential for preventing leaks, backups, and water damage in your industrial plant. Inspect pipes for corrosion or signs of deterioration, repair any leaks promptly, and ensure that drainage systems are clear of debris. You should also consider upgrading your piping to more durable materials to avoid future issues.

You can partner with a reputable provider of industrial piping supply to ensure high-quality replacements and timely maintenance services. They can also help identify potential problem areas and provide solutions to prevent future issues. Choose a company that values safety and quality to ensure the longevity and reliability of your plumbing systems.

Structural Integrity

The overall structural integrity of your industrial plant should not be overlooked when it comes to maintenance efforts. Regularly inspecting roofs, walls, floors, and other structural elements can help identify potential issues such as cracks, leaks, or corrosion before they escalate into major problems. Addressing these issues promptly can help preserve the safety and longevity of your facility. You may also consider implementing a long-term maintenance plan that includes routine check-ups and repairs to maintain the structural integrity of your plant.

Machinery Maintenance

The machinery in your industrial plant plays a crucial role in production processes, so it’s essential to keep them well-maintained. Machinery maintenance can be complicated, but following these four guidelines can help ensure your equipment remains in top working condition:

Regular Cleaning

Dirt, debris, and grime can build up on machinery over time and lead to malfunctions or breakdowns. Regularly cleaning your machines helps prevent this. Use appropriate cleaning products and techniques to avoid damaging sensitive components.

Lubrication

Many machines require proper lubrication to function smoothly. Check manufacturer guidelines for recommended lubricants and schedules, and make sure to follow them closely.

Inspections

Regularly inspecting machinery can help identify any wear and tear or potential issues before they cause significant problems. Keep a log of these inspections and any maintenance or repairs done to each machine.

Training

Proper training for employees who operate machinery is crucial for both safety and maintenance. Make sure all operators are familiar with the equipment they use and know how to properly care for it. You may also want to consider providing ongoing training as new machinery or updates are introduced.

Your machineries are a significant investment for your company, and proper maintenance is essential to protect that investment. By following these guidelines and addressing any issues promptly, you can help ensure your machinery operates efficiently and safely for years to come. Additionally, regularly maintained machinery can also help reduce downtime and increase productivity, ultimately contributing to the success of your facility.

Maintaining the essential infrastructure of your industrial plant is pivotal for ensuring safety, efficiency, and productivity. Focusing on critical components such as electrical systems, HVAC units, plumbing systems, structural integrity, and machinery maintenance can significantly reduce the risk of costly downtime and enhance operational performance. By implementing regular inspections, investing in quality maintenance services, and ensuring proper employee training, you can safeguard the longevity of your plant’s infrastructure and support its continued success.